Compliance Management Module

EHS Insight's Compliance Management Module revolutionizes the way your business handles compliance by offering a tailored solution that fits your unique needs. Whether you’re managing compliance at one site or across dozens, our platform adapts to your organizational structure and regulatory complexity. From automated compliance workflows to EHS audit tracking, we help you maintain control and reduce risk at every level.

Stay Ahead with Automated Compliance Obligation Tracking

Ensure compliance with every regulatory, company, and other requirements by planning work in advance and using automation to get it done.

Watch the video to learn more and see it in action.

Keep Every EHS Obligation on Track, Automatically

Managing environmental, health, and safety obligations across global operations is no small task. EHS Insight’s Compliance Obligations Software makes it simple to track, manage, and verify compliance so nothing gets missed.

From permits to inspection schedules and regulatory filings, you'll have complete visibility into what's due, who's responsible, and whether your team is on track.

Key Features Built for Smarter EHS Compliance

Automated Compliance Workflows

Eliminate manual tasks with automated notifications, assignments, and escalations that help ensure timely resolution and accountability.

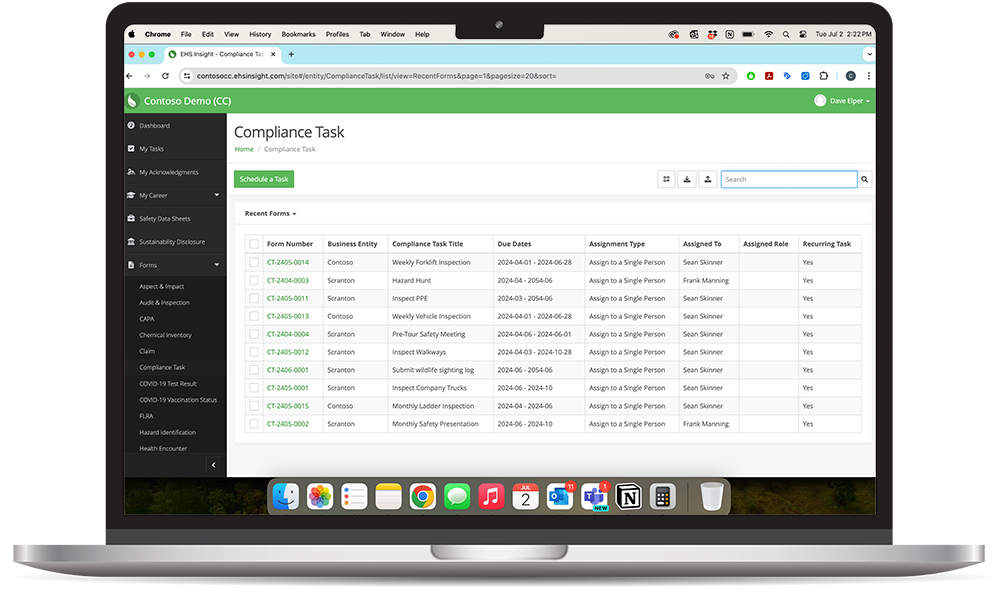

Centralized Obligation Tracking

Capture every requirement, internal or regulatory, on one platform. Easily track completion status, documentation, and responsible parties.

Linked Corrective Actions and EHS Audit Tracking

Connect obligations to audits, findings, and corrective actions to maintain a clear chain of accountability and documentation.

Flexible Scheduling and Recurrence Rules

Set up complex compliance schedules with custom recurrence patterns to match permit cycles, reporting deadlines, and local regulations.

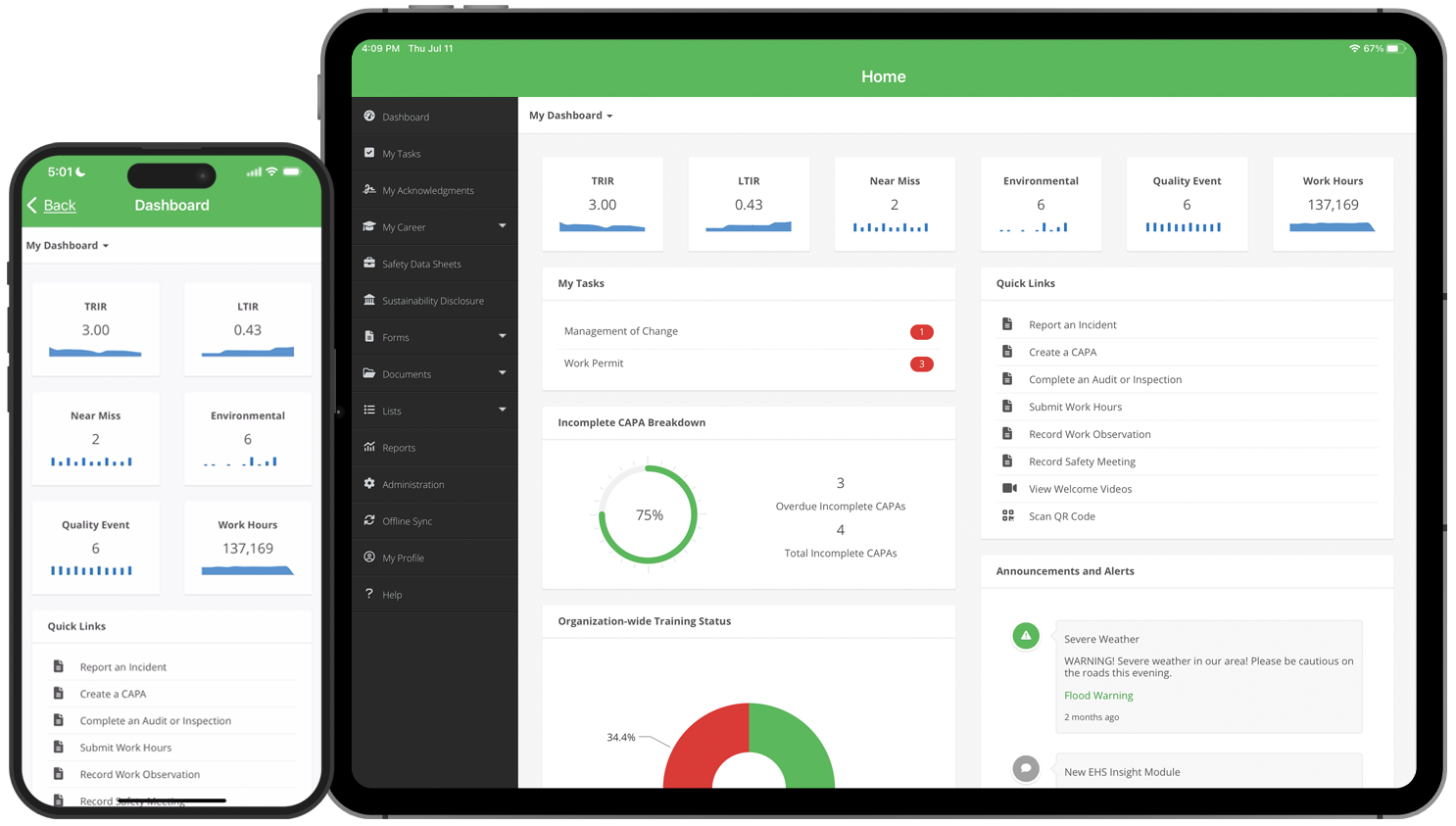

Real-Time Reporting and Dashboards

Gain insight into your compliance performance with dynamic reports and visual dashboards tailored to your team’s priorities.

The Benefits of EHS Insight's Compliance Platform

Report Generation

Reduce the time it takes to complete compliance tasks. Complete tasks with the touch of a button. Generate reports containing notes, corrective actions, photos, and details in a single click. Utilize detailed reports displaying all company-wide compliance tasks or the complete history of individual tasks.

Compliance Calendar

Use the Compliance Calendar to schedule and assign recurring actions and audits, and set reminders and escalations to ensure accountability among employees. Assign Compliance Tasks across multiple Business Entities and use the calendar to view all scheduled tasks or those specifically assigned to you.

EHS Insight Saves Time, Saves Money, and Improves Safety Cultures

What is compliance management software?

Compliance is necessary for businesses to create a safer workplace and reduce their impact on the environment and communities. Compliance software is designed to communicate, monitor, and document different compliance activities. It supports your organization’s adherence to professional standards and the government regulations impacting your industry. EHS Insight’s regulatory compliance software uses a custom mode to configure and tweak data tracking and reporting features to suit your organization, giving you additional flexibility.

What tools are used for compliance management?

Business leaders may employ various tracking and reporting tools to manage their compliance. Different tools exist to handle various forms of compliance. All-purpose compliance management platforms offer generic tools designed for any company or industry. These tools have zero specialization to address technical, governance, and remediation issues. Next, there are industry-specific tools. These provide additional functionality for companies with specialized needs. Finally, there is GRC software. This includes general compliance management tools and incorporates specialized features to streamline workflows and new compliance campaigns. These are among the most robust solutions within the compliance management industry.

How fast can compliance software be implemented?

Get your business compliant and up-to-date using our tailored compliance tracking software! Our implementation process ensures that the compliance management system is completely customized for you, no matter what your industry or services may be. Benefit from a streamlined, efficient solution to avoid any complications with regulations today. EHS Insight goes further than our competitors by mitigating costly implementation fees and standardized support. Your business is unique, so we work with your leadership team to equip you with the skills needed to transform compliance management from a box-checking exercise into a progressive asset. Take advantage of an impactful approach to compliance tracking software, and push forward on transparency and accountability.

Can compliance software be customized?

Make your enterprise compliant with health and safety regulations domestically and overseas. EHS Insight helps you bolster your regulatory intelligence to achieve the high standards of U.S. OSHA, ISO 45001, and RIDDOR. Your customized compliance management software ensures you have the tools to improve employee safety and target risks before an accident happens. Give your employees peace of mind and pass any health and safety audit with flying colors with EHS Insight. End-to-end supply chain compliance is crucial for upholding your expected standards. We build compliance software solutions that allow you to ensure that any enterprise you do business with is just as concerned with risk management and compliance as you are. For companies striving for success, it's essential to maintain the same high standards of quality and performance throughout your supply chain. With our user-friendly compliance monitoring software designed to ensure compliance with industry regulations across every link in the chain, you can rest assured that no detail goes unaddressed in achieving a smooth functioning system — and ultimate business growth!

What are the benefits of compliance software?

Suitable compliance solutions offer a spectrum of benefits for business leaders across every industry. Compliance automation software benefits businesses of all sizes because it can scale as you grow and as your compliance risks increase. Eliminating manual compliance workflows improves productivity while maintaining a higher compliance success rate. You streamline your implementation and facilitate corrective actions by loading your business with relevant frameworks from existing software products. Finally, contacting a software provider with up-to-date solutions allows for easier reporting and tracking so that decision-makers within your organization have the tools they need to address existing and anticipated risks. Investing in compliance management system software preps your organization for anything.

Our Latest Stories

What Should EHS Buyers Prioritize in 2025?

Empower your workforce with EHS Insight.

Over 500,000 users come to depend on EHS Insight for better team collaboration, accountability, and safety visibility.