Are you building your safety management system from scratch? It’s a daunting task, even for seasoned health and safety pros. Use this guide to create a robust safety management system that will make positive changes to your company’s work environment.

Objective of a Safety Management System

Before you can start crafting your safety management system, you’ll want to get buy-in from leadership if you want your efforts to be as impactful as possible. To increase your chance of getting them on board, you need to be able to explain, in simple terms, what a safety management system does and the value it brings to your organization.

Simply put, a safety management system systematizes the way you approach all safety-related activities at your company. From creating policies and procedures to training and deploying safety measures, the safety management system is a comprehensive collaboration of your efforts as an EHS professional.

The goal is to give you a clear-cut way to manage all aspects of your EHS program. By having this solid structure, you have an up-to-the-minute look of what’s happening in your organization regarding inspections, workplace observations, audits, compliance, and training so that nothing falls through the cracks.

How to Implement and Manage a Safety Management System

If you’re starting from the ground up, you’ll have your work cut out for you. It takes a highly detailed, organized person to link every aspect of your environmental, health and safety efforts into a single, working machine.

Get Leadership Approval

If you’re having trouble getting management buy-in, consider hosting a safety training session geared to their level that demonstrates their responsibilities to create a safe work environment. This will ensure they understand potential legal issues and what incidents could cost the company. From there, you can explain how a safety management system can help avoid safety incidents and other costly occurrences.

Create a Program Structure

Once you’ve gotten the green light, you’ll want to create a program structure that encompasses all aspects of your EHS operations, including the following:

- Audits and inspections

- Compliance

- Safety training

- Workplace observations

- Hazards

- Reporting

- Policies and procedures

This planning phase is a huge undertaking because of the level of detail and foresight it requires. You may find yourself going back to tweak this area multiple times as you move forward with your safety management system development.

Implement the Safety Management System

Once you’ve created your plan, it’s time to put it into action. It’s important you provide direct training to those who are involved in the system’s direct oversight. This will be especially helpful as you gauge the system’s effectiveness and generate feedback from other stakeholders.

Measure Your System’s Performance

Don’t set your safety management system on autopilot just yet. Because there are so many moving parts to such a system, it’s critical you continue to observe and measure its performance to see how it’s truly benefiting your organization.

Measuring your results can help you recognize where to make adjustments to add greater impact. Plus, it gives you proof to show leadership or stakeholders that your efforts are working.

Maintain Your Safety Management System

Even after some initial fine-tuning, you should make it a point to review your practices each year (or more frequently). Compliance requirements can change, employees come and go, new machines, equipment, and software are implemented – and your system should be altered to accommodate these changes.

In other words, implementing a safety management system isn’t a one-and-done deal. If you want it to continue delivering good results, you should review it often and make changes when necessary.

Putting the Pieces Together

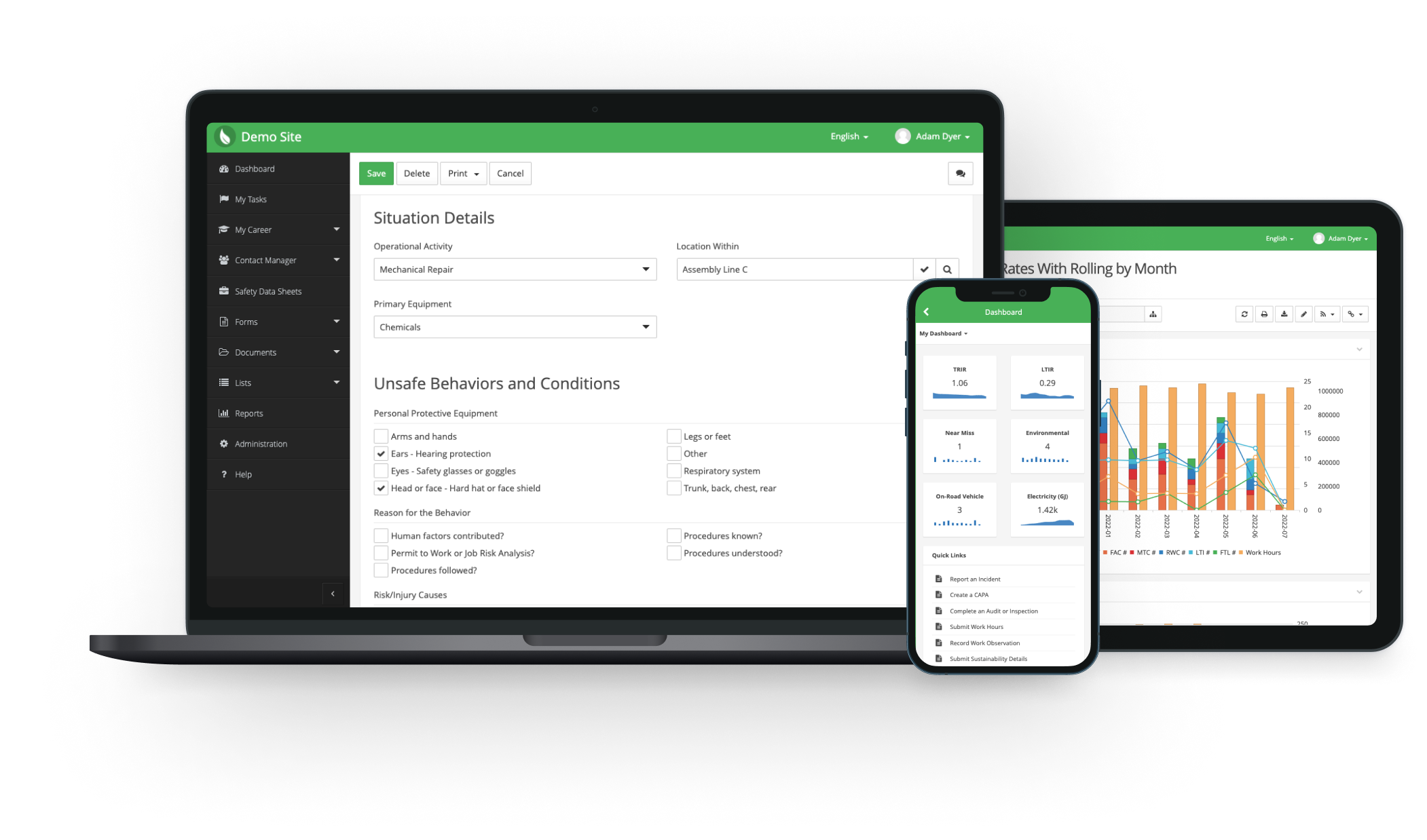

It’s a lot to consider, especially if you don’t already have some of these systems in place. Using EHS software to help you pull the various components together can be a helpful tool, both in the short and long terms.

EHS software not only helps you organize your myriad tasks, it can also help you automate them. You can set reminders for compliance tasks, audits, and training, store documents and other data, and collaborate with your team members.

It’s a streamlined way to set up a comprehensive system without much manual labor. In addition, it can also compile results from the different areas of your program to give you deeper insights into your EHS department. As a result, you get a fully functional system that helps ensure no detail goes unnoticed.

Creating a safety management system is a time commitment, but the rewards of your investment are too great to ignore. You stand to gain improved communication, a greater focus on safety practices, and less chance of important tasks slipping past your radar.

Improving safety is an initiative that everyone in your organization will benefit from. Contact us today for a free trial of EHS Insight and see how it can improve the way you work.