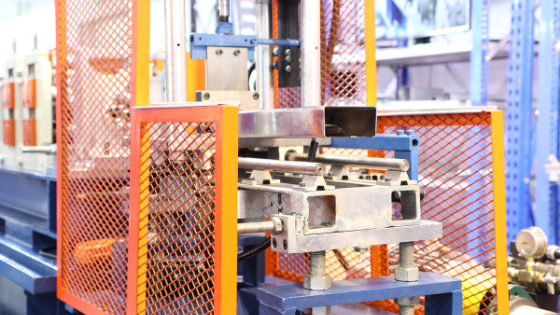

When it comes to machine guarding, you have to know what hazards you’re trying to protect against. Or, rather, you have to know where to guard to prevent hazards.

According to many workplace safety regulations and OSHA standards covering machine guarding, one of the most important areas for machine guarding is the point of operation.

What is the point of operation? How does it factor into machine guarding? And how can you guard employees against hazards at the point of operation? Here’s a quick review of this critical concept in machine guarding.

What are The Three Main Areas of a Machine?

Every machine comprises three essential components: the point of operation, the power transmission device, and the operating controls.

Operating controls are mechanical or electrical controls allowing the operator to cut off power to a machine without leaving their operating position. The power transmission device refers to all parts of a mechanical system that transmit energy to the part of the machine performing the work.

That’s the point of operation, which is where work is performed on the material, such as shaping, cutting, boring, drilling, etc.

Motions and Actions

Because the point of operation is the point at which the work of the machine occurs, it is the point which is most likely to cause immediate harm to a worker. That’s because many potentially hazardous motions and actions occur at the point of operation.

Basic types of hazardous motions include:

- Rotating

- Reciprocating

- Transverse

- In-running nip points

Basic types of hazardous actions include:

- Cutting

- Boring

- Shearing

- Punching

- Bending

As you can see, the types of hazardous motions and actions vary widely depending on the machine in question. The hazards brought on by the point of operation thus depend on the machine in question and how it is being used.

Guarding the Point of Operation

The point of operation is essential to understand because it is the focus point of most of OSHA’s workplace standards related to machine guarding.

Under standard 1910.212 (general requirements for all machines) employers are required to provide one or more methods of machine guarding at areas which expose employees to hazards.

Standard 1910.212(a)(3)(ii) explicitly states, “The point of operation of machines whose operation exposes an employee to injury, shall be guarded. The guarding device shall be in conformity with any appropriate standards or in the absence of applicable specific standards, shall be so designed and constructed as to prevent the operator from having any part of his body in the danger zone during the operating cycle.”

More Essentials of Machine Guarding

What is point of operation? As in many areas of safety, it’s one of the small, basic details that goes a long way in creating a hazard. Even the smallest attention to detail can make all the difference between an average Tuesday and a tragic accident.

If you and your safety team are working to refresh your employees on essential safety concepts, our training software can make it easier to ensure your employees retain information that will save lives.

Related Resource: Why Machinery Industry Professionals Should Care About EHS Performance Improvement